Thermoplastic and Thermosetting

Thermoplastic:

A thermoplastic, or thermosoftening plastic, is a plastic material, polymer, that becomes pliable or moldable above a specific temperature and solidifies upon cooling.

Most thermoplastics have a high molecular weight. The polymer chains associate through intermolecular forces, which weaken rapidly with increased temperature, yielding a viscous liquid. Thus, thermoplastics may be reshaped by heating and are typically used to produce parts by various polymer processing techniques such as injection molding, compression molding, calendering, and extrusion.Thermoplastics differ from thermosetting polymers, which form irreversible chemical bonds during the curing process. Thermosets do not melt, but decompose and do not reform upon cooling.

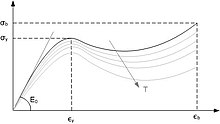

Above its glass transition temperature, Tg, and below its melting point, Tm, the physical properties of a thermoplastic change drastically without an associated phase change.

Thermosetting:

A thermosetting polymer (or plastic), also known as a thermoset, is petrochemical material that irreversibly cures. The cure may be induced by heat, generally above 200 °C (392 °F), through a chemical reaction, or suitable irradiation.

Thermosetting materials are usually liquid or malleable prior to curing and designed to be molded into their final form, or used as adhesives. Others are solids like that of the molding compound used in semiconductors and integrated circuits (IC). Once hardened a thermoset resin cannot be reheated and melted to be shaped differently.

Thermosetting resin may be contrasted with thermoplastic polymers which are commonly produced in pellets and shaped into their final product form by melting and pressing or injection molding.